Wrong, they work exactly the same as they do in N/Atoysrus wrote:Tuned runner lengths are not necessary with Forced Induction.

EOI Custom intake manifold

My understanding of the theory was that tuned length is less important for F/I, but still plays a part. And after playing with a turbo engine on a dyno with nothing changed but runner length and fuel/ign trimming for the different lengths, the power and torque curves definitely change.mrb1 wrote:Wrong, they work exactly the same as they do in N/Atoysrus wrote:Tuned runner lengths are not necessary with Forced Induction.

Cordia, powered by EVO...

- turbo_onion

- Dorifto!

- Posts: 52

- Joined: Thu Feb 03, 2005 11:33 am

- Location: Auckland, NZ

Quick update. Am getting a former CNC'd at a low cost of NZ$350. This is for *hopefully* a perfect sweep from a trumpet to the odd inlet port shape. The former is just an experiment to see if the metal can be streched as much as i need, so i really hope it works. I had a personal meeting with a director of the company doing the machining to discuss what exactly I wanted and he rekons it is gunna be f**kn tricky to make. But hey, im paying goodmoney so he should damn well try. That was monday last week and I havnt heard anything back yet.

If it doesnt work i wont pass the cost of it onto the price, ill just take it and cry :D

Plenum volume is pretty much finalised.

Still havnt found that much info about the runner lengths that will optimise the power, but from what info i can get, it is possible to get slight power and torque increase across a very narrow rev range by wave tuning on a turbo car. I think im going to run with a shorter runner so theoretical better throttle response, which is what im after. Hopefully this doesnt hinder top end power.

If it doesnt work i wont pass the cost of it onto the price, ill just take it and cry :D

Plenum volume is pretty much finalised.

Still havnt found that much info about the runner lengths that will optimise the power, but from what info i can get, it is possible to get slight power and torque increase across a very narrow rev range by wave tuning on a turbo car. I think im going to run with a shorter runner so theoretical better throttle response, which is what im after. Hopefully this doesnt hinder top end power.

Again, not trying to be too picky but you didn't really anwer all of the questions in there

If we ignore tuned lengths (which I'm happy to for a F/I engine), there's still more involved than just plenum volume. The shape of the whole manifold will have an effect on flow and thus power made by the engine.

But really, the big one I'm curious about is how you're planning on mounting injectors and fuel rail onto the manifold (because it's something we have yet to do well ).

).

Cheers,

Adrian

If we ignore tuned lengths (which I'm happy to for a F/I engine), there's still more involved than just plenum volume. The shape of the whole manifold will have an effect on flow and thus power made by the engine.

But really, the big one I'm curious about is how you're planning on mounting injectors and fuel rail onto the manifold (because it's something we have yet to do well

Cheers,

Adrian

Cordia, powered by EVO...

- Starion VR4

- almost postwhore

- Posts: 1293

- Joined: Fri Jan 09, 2004 5:08 pm

- Location: Brisbane

Ummm, sorter lenght runners make more power up top, not more torque, longer length runners make torque, remember the std VR4 inlet, only 1 runner works at low RPM via butterfly & the lenght of the std inlet track is long, as RPM increases the vacuum is lost/switched so both tracks work, because they R of different lenghts this creats different velociteys in the port/head resulting it swirl in the combustion chamber. If u work on the STD lenghts U will improve either top/bottom end. As it is a perforrmance orentated result U may want, then short runners is what is required. Do U need money to fund machining costs if so PM me i will payin advance. :beer

30PSI,2.4L! Wolf 3D Ver 4. VR4 Head.

- turbo_onion

- Dorifto!

- Posts: 52

- Joined: Thu Feb 03, 2005 11:33 am

- Location: Auckland, NZ

I should be right at the moment but thanks anyway.Starion VR4 wrote: Do U need money to fund machining costs if so PM me i will payin advance. :beer

I havnt got around to that side of the design just yet. I dont actually have a vr4 mani to look at so im knid of going blind and using my eyecrometer whenever I see someone with a vr4 parked somewhere, I wander on over ask ask for a look. I was expecting to fit the fuel rail and injectors after the manifold has been fitted to the side of the head, so that I can just make some mount flanges and tack them onto the runners at the right points. I dont know of any problems with this so far? if you can think of any please let me knowCordzboy wrote:But really, the big one I'm curious about is how you're planning on mounting injectors and fuel rail onto the manifold (because it's something we have yet to do well).

As for the plenum shape, that will be a guess and check on the first prototype. If there is too much air turbulance then out comes the die grinder. Its all good drawing it in cad but that doesnt really give me a physical thing to play with. So like I say im going at this entire thing kind of blind

It seems runner length may need more research. If anyone can volunteer for this that would be great, Google seems to be too vast for my patience, but I have been through a lot of shit. I was wondering if anybody knows of a design book or something, rather than just going off peoples comments and guesses!

Also, I need all the criticism I can get so dont worry about being too picky or whatever :D

Nope, I just realised that the vr4's have the injectors and fuel rail going onto the head, not the intake manifold like the SOHC multipoint setupturbo_onion wrote: I havnt got around to that side of the design just yet. I dont actually have a vr4 mani to look at so im knid of going blind and using my eyecrometer whenever I see someone with a vr4 parked somewhere, I wander on over ask ask for a look. I was expecting to fit the fuel rail and injectors after the manifold has been fitted to the side of the head, so that I can just make some mount flanges and tack them onto the runners at the right points. I dont know of any problems with this so far? if you can think of any please let me know

The big problem I see here is that if you're making it from sheet metal you won't have anything to die grind - it'll make a very unhelpful hole in your manifold.turbo_onion wrote: As for the plenum shape, that will be a guess and check on the first prototype. If there is too much air turbulance then out comes the die grinder. Its all good drawing it in cad but that doesnt really give me a physical thing to play with. So like I say im going at this entire thing kind of blind

turbo_onion wrote: It seems runner length may need more research. If anyone can volunteer for this that would be great, Google seems to be too vast for my patience, but I have been through a lot of shit. I was wondering if anybody knows of a design book or something, rather than just going off peoples comments and guesses!

Also, I need all the criticism I can get so dont worry about being too picky or whatever :D

Take a look at some of the aftermarket manifolds available already for a good start on runner lengths. There's plenty of good books out there on wave and acoustic tuning of manifolds - take a quick trip to your library and you'll find some. But, to narrow it down for you, try searching for info on helmholtz resonance - it should lead into intake design.

Cordia, powered by EVO...

- turbo_onion

- Dorifto!

- Posts: 52

- Joined: Thu Feb 03, 2005 11:33 am

- Location: Auckland, NZ

Yea i was thinking of just getting one prototype and then changing it if its all wrong. Are you looking at the "step" as such on the back end of the manifold by chance?Cordzboy wrote:

The big problem I see here is that if you're making it from sheet metal you won't have anything to die grind - it'll make a very unhelpful hole in your manifold.

Cheers, ill do some research into the Helmholtz as soon as I get an opportunityCordzboy wrote:

Take a look at some of the aftermarket manifolds available already for a good start on runner lengths. There's plenty of good books out there on wave and acoustic tuning of manifolds - take a quick trip to your library and you'll find some. But, to narrow it down for you, try searching for info on helmholtz resonance - it should lead into intake design.

-

redzone

- racking my brains

- Posts: 5900

- Joined: Thu Oct 06, 2005 10:46 pm

- Location: sunshine coast qld

- Contact:

i actually saw an article in an american import tuning mag a while back on this exact thing, for a 4G63 dohc, they actually made 3 different manifolds and dyno tested them, they were more concerned with the taper of the runner going into the port than runner length (i think they optimised that beforehand on paper) so if u could find out what mag it was and what the content was in the article then that would be a big help..

sorry i cant remember what the mag was, i`m kicking myself for not buying it!! :glare:

sorry i cant remember what the mag was, i`m kicking myself for not buying it!! :glare:

Fibreglass airdams $370, fibreglass front bumpers $260, reco drag links $165, alloy radiators $925 (unpolished), h/l switch rebuilds $125, all plus freight.

Coxs Automotive (07)54433507 3/5 Service st Maroochydore Q

www.facebook.com/coxsautomotive

www.coxsautomotive.com.au

Coxs Automotive (07)54433507 3/5 Service st Maroochydore Q

www.facebook.com/coxsautomotive

www.coxsautomotive.com.au

- turbo_onion

- Dorifto!

- Posts: 52

- Joined: Thu Feb 03, 2005 11:33 am

- Location: Auckland, NZ

Cheers redzone, ill try finding that one on my travels through the vast wilderness that is googleredzone wrote:i actually saw an article in an american import tuning mag a while back on this exact thing, for a 4G63 dohc, they actually made 3 different manifolds and dyno tested them, they were more concerned with the taper of the runner going into the port than runner length (i think they optimised that beforehand on paper) so if u could find out what mag it was and what the content was in the article then that would be a big help..

sorry i cant remember what the mag was, i`m kicking myself for not buying it!! :glare:

- turbo_onion

- Dorifto!

- Posts: 52

- Joined: Thu Feb 03, 2005 11:33 am

- Location: Auckland, NZ

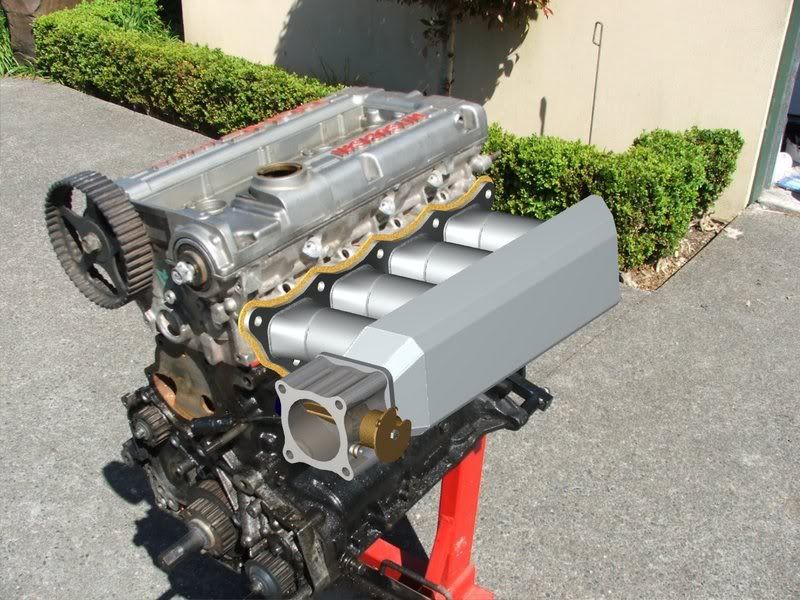

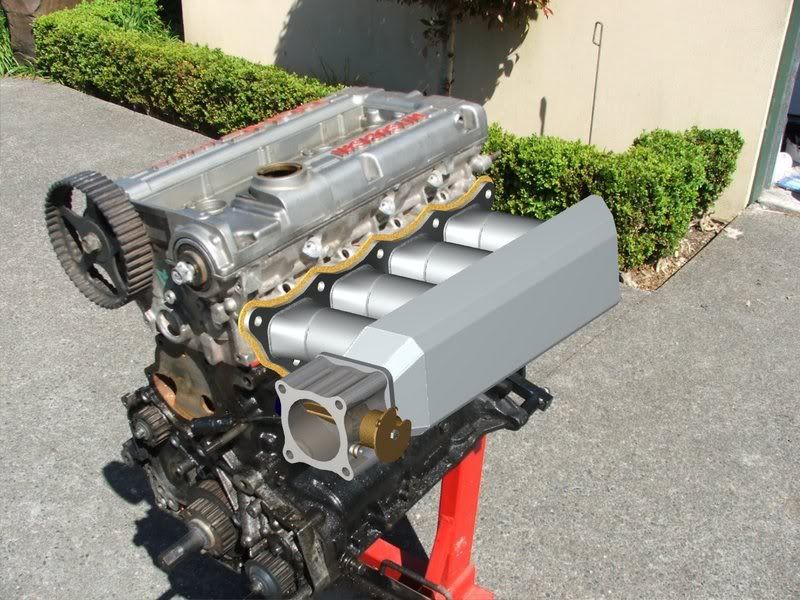

almost finished cad paper and had to do a bit of photoworks for the manifold:

thoughts?

thoughts?

Last edited by turbo_onion on Mon Oct 16, 2006 7:25 pm, edited 1 time in total.

-

redzone

- racking my brains

- Posts: 5900

- Joined: Thu Oct 06, 2005 10:46 pm

- Location: sunshine coast qld

- Contact:

i just saw that hi octane has now got available exactly what we`re making here! it is meant for transverse or rear wheel drive applications, the plenum unbolts so u can reverse it....

your one looks nice though, i`ll find out what the hi octane one is worth anyways. could be ridiculously expensive!

your one looks nice though, i`ll find out what the hi octane one is worth anyways. could be ridiculously expensive!

Fibreglass airdams $370, fibreglass front bumpers $260, reco drag links $165, alloy radiators $925 (unpolished), h/l switch rebuilds $125, all plus freight.

Coxs Automotive (07)54433507 3/5 Service st Maroochydore Q

www.facebook.com/coxsautomotive

www.coxsautomotive.com.au

Coxs Automotive (07)54433507 3/5 Service st Maroochydore Q

www.facebook.com/coxsautomotive

www.coxsautomotive.com.au

- turbo_onion

- Dorifto!

- Posts: 52

- Joined: Thu Feb 03, 2005 11:33 am

- Location: Auckland, NZ

- Starion VR4

- almost postwhore

- Posts: 1293

- Joined: Fri Jan 09, 2004 5:08 pm

- Location: Brisbane

- turbo_onion

- Dorifto!

- Posts: 52

- Joined: Thu Feb 03, 2005 11:33 am

- Location: Auckland, NZ

wow the pressures really on now! I have the mould for the the funnel getting case hardened as we speak, i have done two prototypes with different size aluminium and it works beautifully. They have been welded up so now all i have to do is get hold of some proper pipe that i will use and then send the drawings off to be lasercut and CNC folded. Uni will have finished after the 8th of Nov so the production will be full on.

As for sending the cad drawing, no offence intended, but that would be cutting my own lunch! I will sort something out. still dont know prices

As for sending the cad drawing, no offence intended, but that would be cutting my own lunch! I will sort something out. still dont know prices

Who is online

Users browsing this forum: No registered users and 11 guests