My JB

Posted: Wed Apr 20, 2011 12:02 am

After 12 years of the car being un-registered, surviving a marriage and divorce, i needed a project, get the car back on the road, it took about 3 months to get it registered again, thanks to shannon, i managed to get a fuel tank and guard from him, replaced the fuel pump, brake and clutch master cylinders and gave it a good clean up

the first project after being registered was to do the multi-point haltech conversion. i had started a custom manifold many years ago and never finished it, so after several trips to my mates machine shop, i finished milling the manifold and he welded it up, the next thing was to sort out the crank pick up, the new manifold did not have a provision for a distributor, i found a zero speed hall effect transistor from farnell components, i then milled a housing for it to mount where the balance shaft belt adjuster would go, i also milled 2 teeth of the balance shaft drive pulley, missing tooth, i setup a test bench, made the amplifier circuit for the hall effect and tested it on the haltech, all worked nicely, next was to build the ignition ignitors, that was fairly straight forward, got some bosch BIP737 ignition drivers from megasquirt, milled up a heat sink housing, and mounted the transistors and the current limiting resistors, the problems begin, haltech on there primary ignition channel drive the output at 8 volts, the second output for the second coil is a generic output, it is driven at 12 volts, this exceeded the maximum base voltage of the transistor of 9.6 volts, the problem was it would start and run, them after a while would drop 2 cylinders, after a lot of time on the scope i found the problem, a little more circuitry, the problem solved, car was running.

After a lot of road tuning and data logging, i was dropping boost after 4500 rpm in 4th gear, the first thing i changed was the air box, i wanted to keep the original air box because it is quite a good size, the air inlet into the box was quite small, so i removed the 2 inch diameter air inlet and fabricated a 4 inch diameter pipe, i removed the pipe bracket from the inner guard , the new pipe on the air box i made long enough to marry up to the existing hole in the inner guard, the original hole in the inner guard is 4 inch in diameter. i added a 4 inch pod filter straight inside the original air box. after this mod, i maintained 22 psi boost till 5500 rpm.

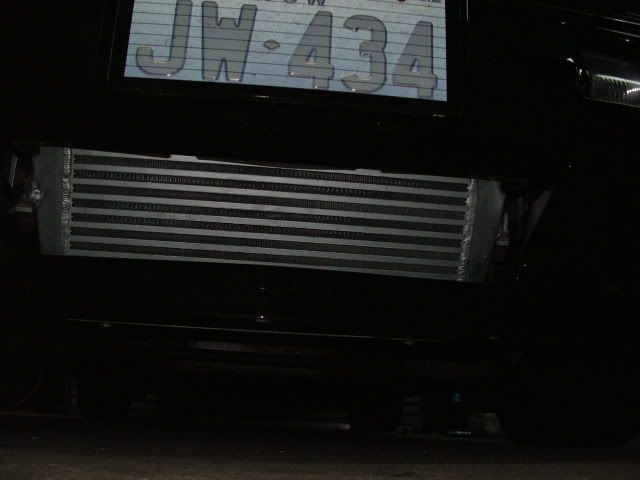

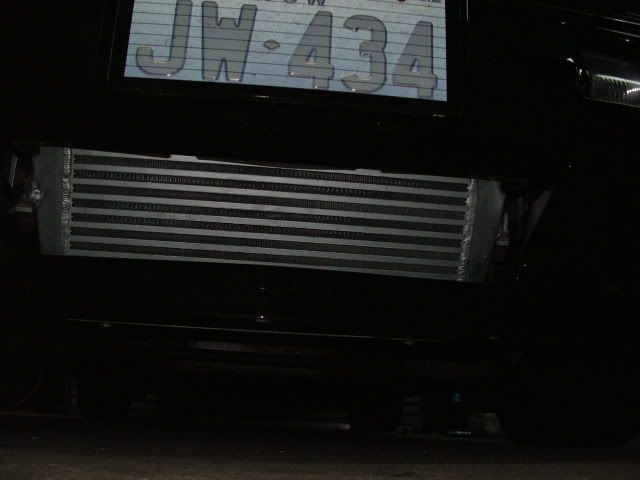

the next mod was to replace the factory JD intercooler. i found a 680X300X76mm bar and plate intercooler, this had end mounts, i removed these and welded pipes into the top similar to the factory

i welded brackets to the side of the intercooler and mounted it where the factory intercooler mounts

i made 2 1/2 inch intercooler piping where the factory piping runs, tried to keep it neat

After these mods i also mill up a air horn for the turbo housing, with a 16g wheel in a standard JD housing, there is only about 1mm of metal left, i moved the power steering reservoir to the inner guard and changed the power steering high pressure hose to a banjo fitting, this allowed me to straighten the air into the turbo, i also upped the boost, the maximum boost i can get on the 16g is 28psi, it maintains it to about 6000rpm

A new 3 inch exhaust was also fitted to replace the existing 2.5 system.

I have also fitted D2 coilovers in the last few months, a good mod, still rides quite well

I will add more over the next few weeks

the first project after being registered was to do the multi-point haltech conversion. i had started a custom manifold many years ago and never finished it, so after several trips to my mates machine shop, i finished milling the manifold and he welded it up, the next thing was to sort out the crank pick up, the new manifold did not have a provision for a distributor, i found a zero speed hall effect transistor from farnell components, i then milled a housing for it to mount where the balance shaft belt adjuster would go, i also milled 2 teeth of the balance shaft drive pulley, missing tooth, i setup a test bench, made the amplifier circuit for the hall effect and tested it on the haltech, all worked nicely, next was to build the ignition ignitors, that was fairly straight forward, got some bosch BIP737 ignition drivers from megasquirt, milled up a heat sink housing, and mounted the transistors and the current limiting resistors, the problems begin, haltech on there primary ignition channel drive the output at 8 volts, the second output for the second coil is a generic output, it is driven at 12 volts, this exceeded the maximum base voltage of the transistor of 9.6 volts, the problem was it would start and run, them after a while would drop 2 cylinders, after a lot of time on the scope i found the problem, a little more circuitry, the problem solved, car was running.

After a lot of road tuning and data logging, i was dropping boost after 4500 rpm in 4th gear, the first thing i changed was the air box, i wanted to keep the original air box because it is quite a good size, the air inlet into the box was quite small, so i removed the 2 inch diameter air inlet and fabricated a 4 inch diameter pipe, i removed the pipe bracket from the inner guard , the new pipe on the air box i made long enough to marry up to the existing hole in the inner guard, the original hole in the inner guard is 4 inch in diameter. i added a 4 inch pod filter straight inside the original air box. after this mod, i maintained 22 psi boost till 5500 rpm.

the next mod was to replace the factory JD intercooler. i found a 680X300X76mm bar and plate intercooler, this had end mounts, i removed these and welded pipes into the top similar to the factory

i welded brackets to the side of the intercooler and mounted it where the factory intercooler mounts

i made 2 1/2 inch intercooler piping where the factory piping runs, tried to keep it neat

After these mods i also mill up a air horn for the turbo housing, with a 16g wheel in a standard JD housing, there is only about 1mm of metal left, i moved the power steering reservoir to the inner guard and changed the power steering high pressure hose to a banjo fitting, this allowed me to straighten the air into the turbo, i also upped the boost, the maximum boost i can get on the 16g is 28psi, it maintains it to about 6000rpm

A new 3 inch exhaust was also fitted to replace the existing 2.5 system.

I have also fitted D2 coilovers in the last few months, a good mod, still rides quite well

I will add more over the next few weeks