Page 1 of 3

Twin cam conversion (lots of pics)

Posted: Fri Aug 15, 2008 9:24 pm

by avandull

Been busy in my new shed.

I have had no life for months.

Here are some pics

XF falcon throttle body

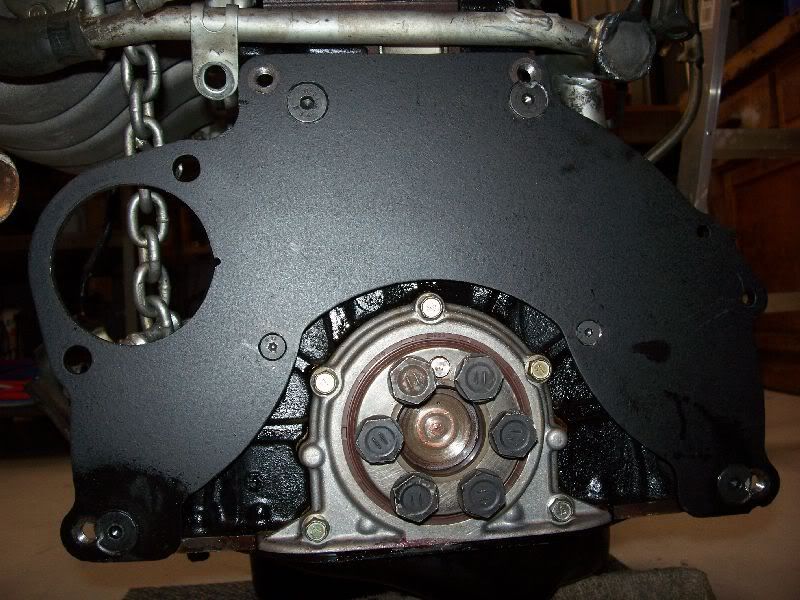

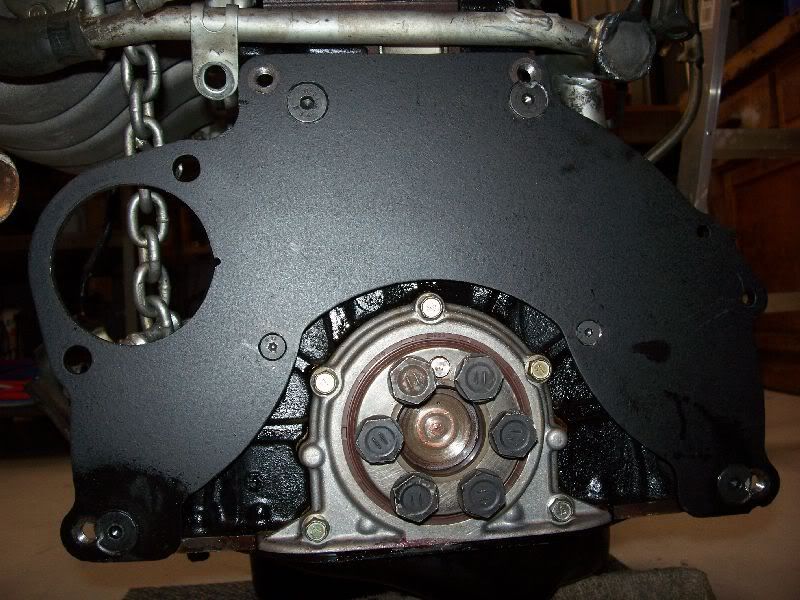

Adaptor plate made from 8mm steel

Modified coolant piping

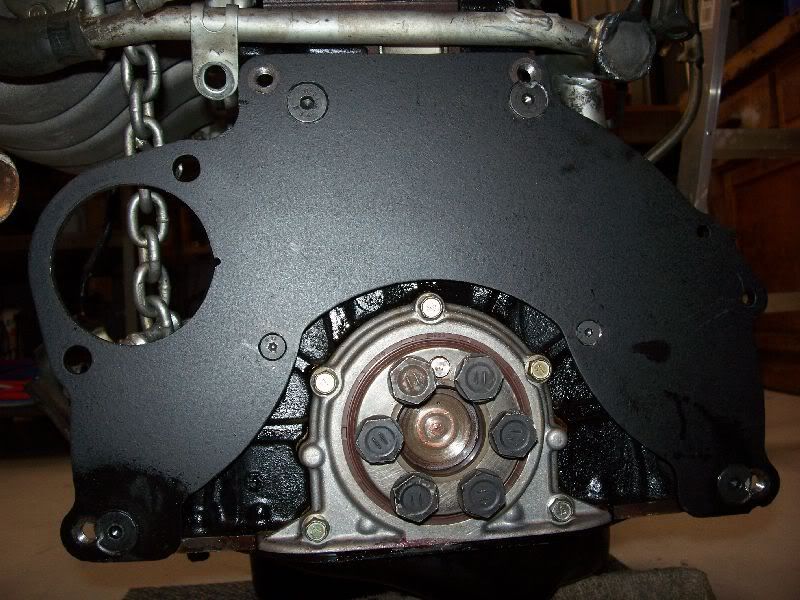

balance shafts removed

Custom exhast manifold made from 40mm steam pipe

750cc injectors

in she goes

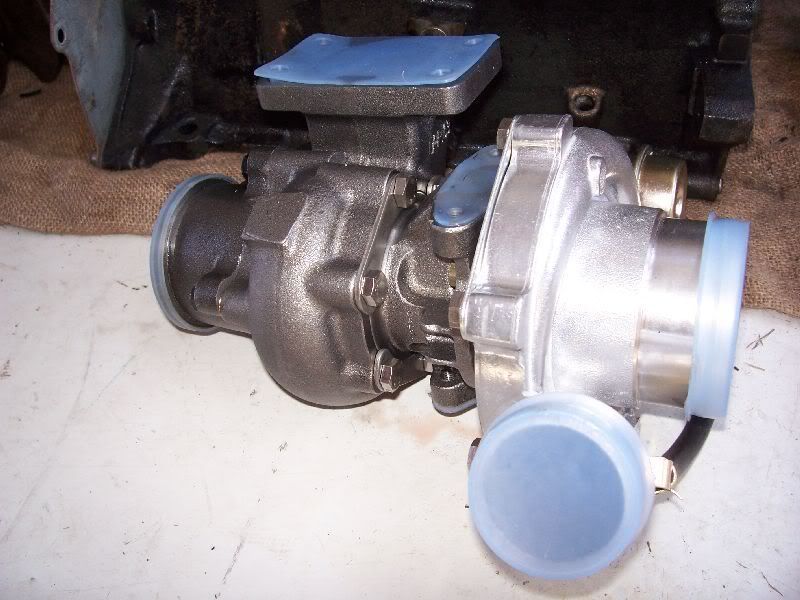

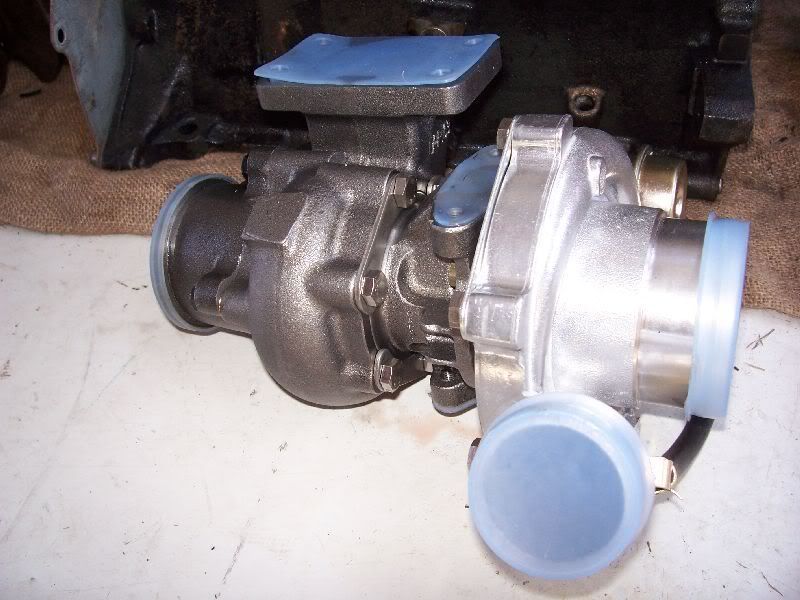

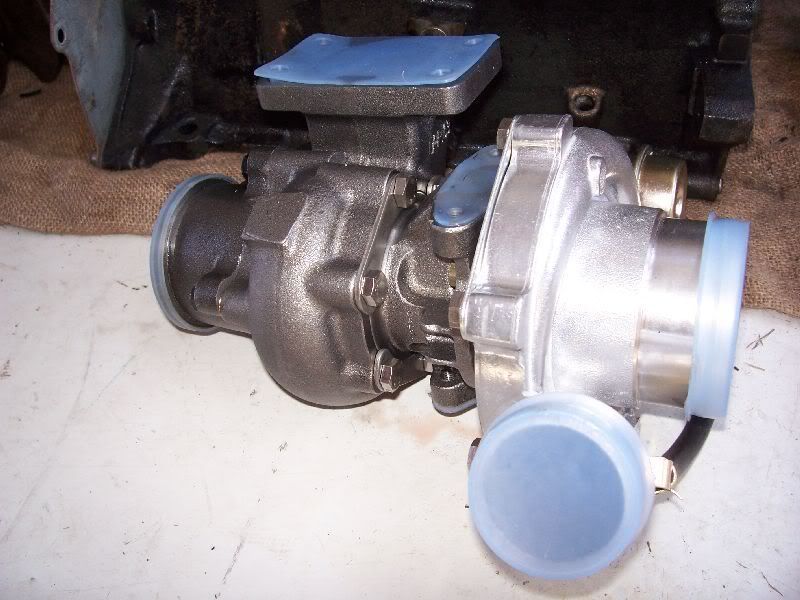

Cheap ebay turbo. I will let you all know how it goes

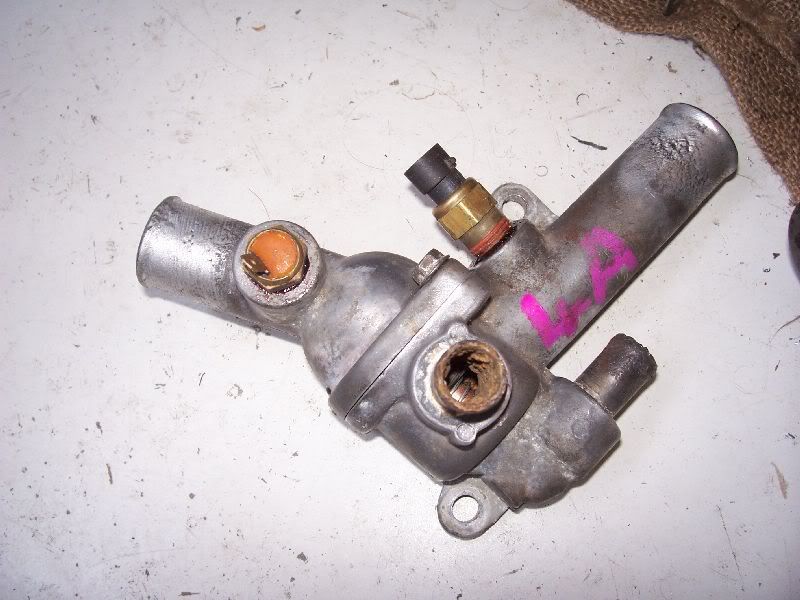

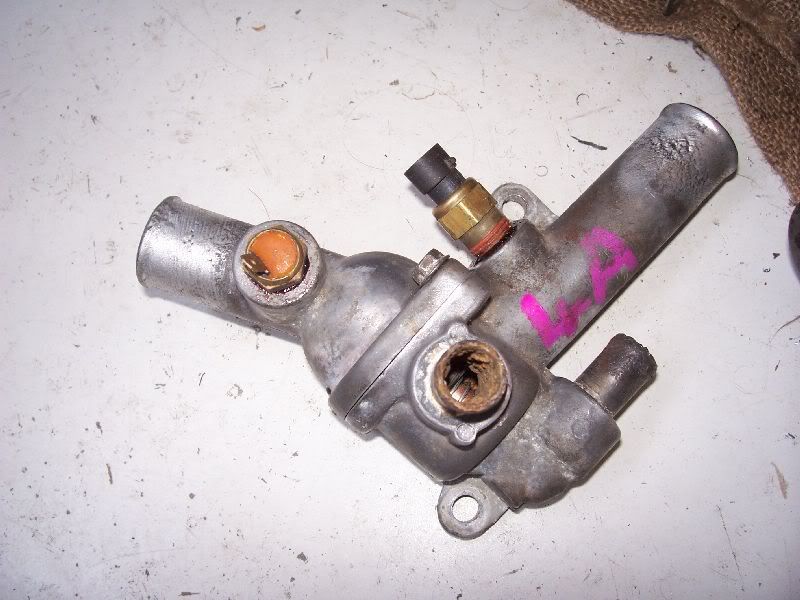

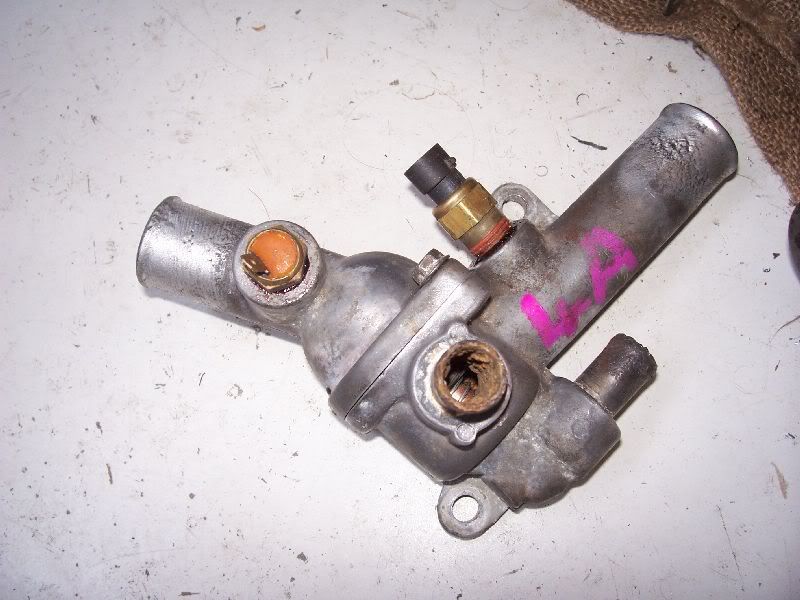

Corolla thermostat housing

Intercooler installed. 600x300x100. I moved the intercooler flanges to suit.

Posted: Fri Aug 15, 2008 9:55 pm

by groupAralliart

a life well wasted! Looks great, I am keen to hear how it goes.

Posted: Sat Aug 16, 2008 5:49 am

by OLD FART

Nice work mate WELL DONE !!!!!!!!!!!!!!!!!!! :beer

Posted: Sat Aug 16, 2008 8:04 am

by FST4RD

That is sweet!

Posted: Sat Aug 16, 2008 10:22 am

by S0LJAH

looks good mate

i had a corolla thermostat hosuing that i toyed ith using on my twincam conversion but in the end just went with the stock one remounted

Posted: Sat Aug 16, 2008 11:18 am

by Komeuppance

Nice!! What'd you do about the CAS to firewall clearance?? BFH (Big f'n Hammer)??

More info on your sweet looking adapter plate!! What grade/strength bolts are those?? And what flywheel did you use??

-Robert

Posted: Sat Aug 16, 2008 1:36 pm

by Lunacy

Hey man nice work. Couple of questions:

What computer are you running?

How did u get the idle sorted on the xf throttle body?

Cheers

Posted: Sat Aug 16, 2008 3:04 pm

by redzone

nice one!

been wondering where you'd got to :beer

Posted: Sat Aug 16, 2008 8:59 pm

by avandull

I am using a Haltech E6K ECU.

I have no idle control at the moment. Does not really need it.

The CAS clears the firewall by less then 1 mm. I did not hammer the firewall but I will next time the motor is out to increase clearance.

The adaptor plate

The bolts are turned up in a mates lathe. They are a 12.9 tensile, however machining them has reduced the tensile strength. This was because a countersunk high tensile bolt is not avalible in a 10mm x 1.25mm. So I mechined this thread in to the shank of a longer bolt.

Posted: Sun Aug 17, 2008 12:48 am

by WidebodyWoody

Awesome ride. I LOVE the IC piping and the way its mounted. Should have nice response. :beer

Posted: Sun Aug 17, 2008 8:15 am

by avandull

Standard starion flywheel.

Intercooler piping 3inch stainless

Posted: Mon Aug 18, 2008 8:07 pm

by Komeuppance

Damn... custom bolts... that's intense.

It's beautiful!!

MORE pics!!!!

-Robert

Posted: Mon Aug 18, 2008 10:47 pm

by redzone

yep thats the most efficient way to run the cooler on a starion, thats how i do my cars. can make it 100% legal too even though you're cutting through the rad support, by having a fixed piece of pipe welded as it passes through the rad support, with a silicone joiner either side to go to the next piece of pipe..

Posted: Tue Aug 19, 2008 1:21 am

by Xentro

Nice work,

How did you make the adapterplate? cad drawing or just measurements.

I was thinking of making the same plate.

Posted: Tue Aug 19, 2008 7:53 am

by WidebodyWoody

Thanks dave, I didn't think about the welding bracket. Yeah I wanted to run my piping that way too. I will definetly keep the bracket in mind.

Yeah car looks sweet. Do you know how it drives yet? Or how much HP?