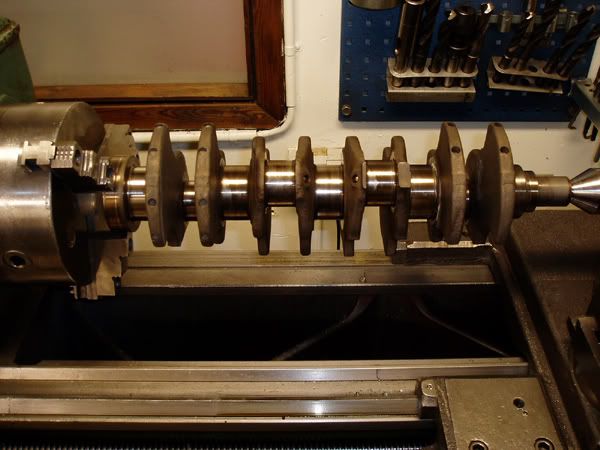

Smudge and crap.

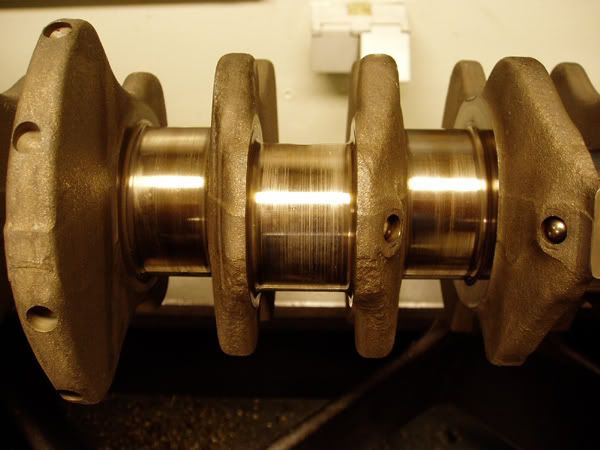

Looking better here:

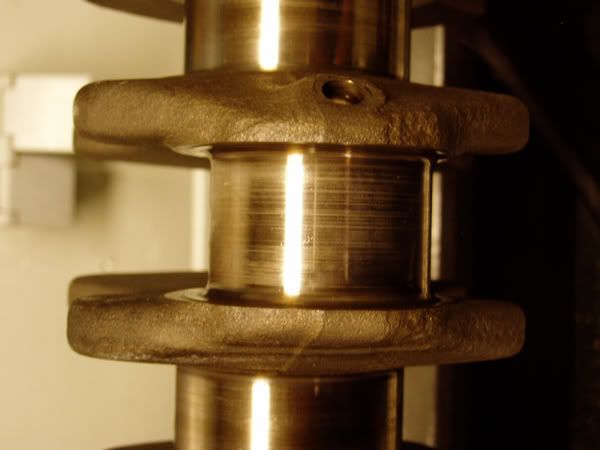

Took a few turns in the washer for this.

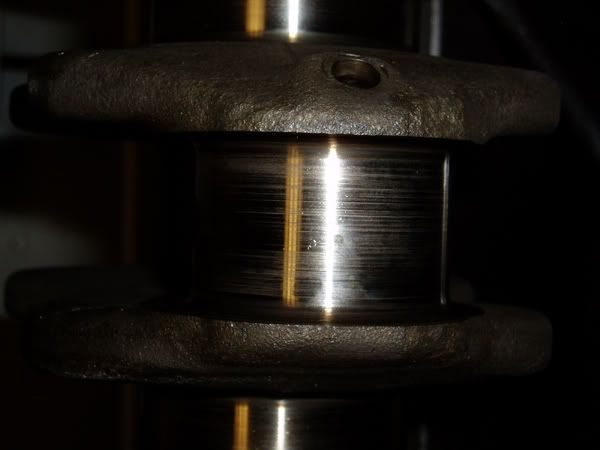

-Perfect!

quest wrote:don't try explaining that to her tho..... just leave. lolWANTSOM wrote:Personally, I find sloppy boxes very unsatisfying. I like them tight and taught to the point that if you dont have to push to get it in then its probably too old and time to get a new one :P

500Hp is actually not at all a problem, are you just trying to make me work faster :Dthrash wrote:500 hp from that motor.. not possible :x

(hint: that means hurry up with it and prove me wrong :D)

Thank you! the pockets are not so deep at all :( I do all work my self, the parts for the engine will be the biggest problem to finance. Since I work in an engine laboratory with engine development I have a great possibility to use some equipment from work. :) The project is a slow one, I must warn you about that, what you see is work from a 3 year period....Land Rocket wrote:Wow, that is a lot of work, and some deep pockets.

Your doing a great job on the car, keep it up.

quest wrote:don't try explaining that to her tho..... just leave. lolWANTSOM wrote:Personally, I find sloppy boxes very unsatisfying. I like them tight and taught to the point that if you dont have to push to get it in then its probably too old and time to get a new one :P

quest wrote:don't try explaining that to her tho..... just leave. lolWANTSOM wrote:Personally, I find sloppy boxes very unsatisfying. I like them tight and taught to the point that if you dont have to push to get it in then its probably too old and time to get a new one :P

Users browsing this forum: No registered users and 2 guests